|

All additional information on other types of swimming pools, pool technics, water maintenance, whirlpools and additional equipment can be found on individual sites of the members of the ROYAL DOLPHIN group.

More on the Royal Dolphin group at www.royaldolphin.info |

Technical descriptions of STRONG LINE pool coversThe ROYAL DOLPHIN STRONG LINE retractable covers are distinguished by their exceptional robustness and strength. They are suitable for larger above-standard cover dimensions (even over 25 m) and locations with lots of snow. It is for this reason that they are also suitable for outdoor areas of restaurants, hotels and bars as well as for large public buildings such as public swimming pools and spas (even for pools with Olympic dimensions). This particularly applies to retractable covers with double-layer "Termopan" glass and tinted ceilings. An exceptionally strong aluminium structure is additionally supported by steel profiles providing additional strength. Load-bearing profiles are available in different cross-section dimensions. The cross-section is calculated according to the customer's requirements and glazing type. The basic versions of the STRONG LINE covers already include fully transparent side walls and a double-layer polycarbonate ceiling, which provides them with exceptional resistance to any weather conditions and mechanical damage. Covers with glass side walls or double-layer "Termopan" glazing, etc., are also available. These covers are not merely intended to protect against dirt or for safety reasons (children and pets), but create a type of conservatory with one great advantage in comparison with classical conservatories: these covers enable the enclosed surface to be fully (or partially) opened during warm summer days. A special feature of these covers is that they do not slide on installed rails (except for specific cover versions - cover structure supported by posts, etc.), but use integrated rollers for sliding, which enables the installation of the cover on a non-level surface. All covers can be additionally fitted with a battery powered electric motor mechanism with remote control, which is powered by solar cells, and other additional equipment. In practice, all covers and details are manufactured in accordance with the customer's wishes and needs, which makes each cover one of a kind. Due to their properties, STRONG LINE pool covers are always manufactured according to the customer's requirements, whereby there are practically no limitations as regards the design, load-bearing capacity and dimensions.

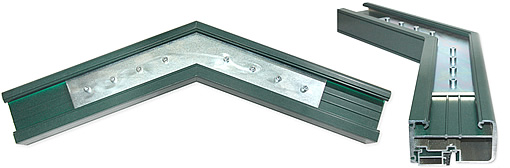

LOAD-BEARING STRUCTURE OF THE POOL COVERThe load-bearing structure is composed of aluminium profiles additionally reinforced with steel profiles.  The entire STRONG LINE cover structure is designed according to the pool dimensions, weather conditions to which the cover will be exposed (e.g. strong wind, snow, etc.) and any additional customer requirements (double-layer Termopan glass, etc.). Based on these factors, the necessary dimensions, and profile and other bearing element numbers are calculated. Therefore, load-bearing aluminium profiles of different dimensions are used for these cover models. The aluminium profile cross-section dimensions for STRONG LINE covers range from 5.5 × 10 cm or 12 × 7 cm to 22 × 9.5 cm.

The standard colours are RAL 9010 white, RAL 1010 bright white, RAL 6005 green and RAL 8017 brown. However, you can choose practically any colour of aluminium colour structure (usually for an additional payment of 3 % of the pool cover price).

The structure of the cover can easily bear the weight of a person, which is of extreme importance during installation and later on when cleaning the cover

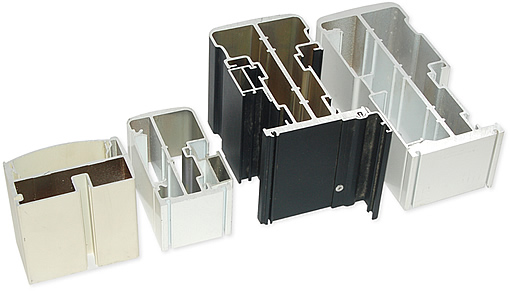

GLAZINGSTRONG LINE covers include fully transparent side walls made of flexible or hard organic glass (flexible polymethacrylic or hard polycarbonate) and a double-layer polycarbonate ceiling, which provides them with exceptional resistance to any weather conditions and mechanical damage. Covers with glass side walls or double-layer "Termopan" glazing, double-layer laminated glass, etc., are also available. Examples of side wall glazing for STRONG LINE pool covers:

Examples of ceiling glazing for STRONG LINE pool covers:

CONSTRUCTION ELEMENTSAll screws and other metal elements are made of stainless steel, handles are made of technopolymer (polyamide), and rollers are fitted with a special rubber lining which enables movement on a non-level surface (porphyry, paving stones, etc.) and stainless steel bearings.

RUBBER SEALS

To seal the cover and stop the wind, the gaps between the cover segments are filled with rubber seals, and along the bottom edge (along the rollers), special brush seals are attached to the cover (see the figure on the right).

NUMBER OF SEGMENTSThe number of segments is always determined according to a specific version of the pool cover and can be adapted to the customer's wishes, for example:

Cover segments are available in different heights and widths and can be designed to slide on semi-circular rails, etc.

COVER SEGMENT SLIDING ON ROLLERS (covers without rails)Most STRONG LINE pool cover versions do not slide on installed rails, but use integrated rollers for sliding, which enables the installation of the cover on a non-level surface. In special cases (greater widths, special versions, etc.), the covers may be designed to slide on fixed rails made of strong INOX guides.

SLIDING WALLS OF THE COVERS AND DOORSThe number of sliding walls and doors in the STRONG LINE pool covers is optional and depends on the customer's requirements. Front and side walls can be equipped with different kinds of doors and windows. In the majority of versions, the front wall within a range of up to 6 m can be retracted one segment backwards (or it can be completely removable), whereas for ranges of larger covers, one front wall is removable.

SPECIAL ELECTRICAL EQUIPMENT

DELIVERY AND INSTALLATION

|

The entire glazing is sealed with various versions of rubber profiles, depending on the specific requirements (glazing thickness and type, etc.).

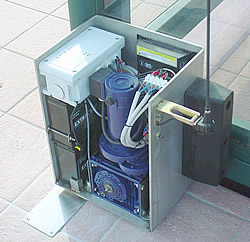

The entire glazing is sealed with various versions of rubber profiles, depending on the specific requirements (glazing thickness and type, etc.). STRONG LINE pool covers can be additionally fitted with battery powered electric motor mechanisms with a remote control of the segment movement, which is powered by solar cells (no need for electrical cables). Particularly with larger covers or covers fixed to a building wall, this mechanism facilitates opening and closing the cover.

STRONG LINE pool covers can be additionally fitted with battery powered electric motor mechanisms with a remote control of the segment movement, which is powered by solar cells (no need for electrical cables). Particularly with larger covers or covers fixed to a building wall, this mechanism facilitates opening and closing the cover. Delivery and installation depend on the manufacturing method and cover dimensions, as well as the accessibility of the installation location. Smaller covers can usually be factory-assembled by the manufacturer and are as such delivered to the installation location. This manner of delivery requires free access by lorry as close to the installation location as possible, or a car jack, and in some cases even a helicopter can be used.

Delivery and installation depend on the manufacturing method and cover dimensions, as well as the accessibility of the installation location. Smaller covers can usually be factory-assembled by the manufacturer and are as such delivered to the installation location. This manner of delivery requires free access by lorry as close to the installation location as possible, or a car jack, and in some cases even a helicopter can be used. Larger covers, irregularly shaped covers or covers with glass side walls, as well as covers to be installed at difficult to access locations are delivered in parts, which are assembled at the location. The assembly of the pool cover requires 2 to 3 days (if carried out by 3 or 4 fitters), but it can also take a week or more in case of larger or more complex structures.

Larger covers, irregularly shaped covers or covers with glass side walls, as well as covers to be installed at difficult to access locations are delivered in parts, which are assembled at the location. The assembly of the pool cover requires 2 to 3 days (if carried out by 3 or 4 fitters), but it can also take a week or more in case of larger or more complex structures.